Increased conveyor system productivity through LubX® CV

Haren – Röchling presents LubX® CV, the new sliding material especially for systems and machinery used in conveyor technology and automation. This new material was developed for systems intended to be operated at higher velocities and pressure loads, meaning increased productivity. Scientific research shows: This material significantly improves system performance and efficiency. Even when used for high-load applications, it retains its excellent sliding characteristics and high wear resistance.

In addition to testing the material in the company-owned laboratory specifically equipped for sliding materials, Röchling had scientific inspections carried out by the Institute for Material Handling and Plastics of the Chemnitz University of Technology and the Erlangen University, Institute of Polymer Technology. The resulting data shows that LubX® CV offers measurable advantages over comparable materials.

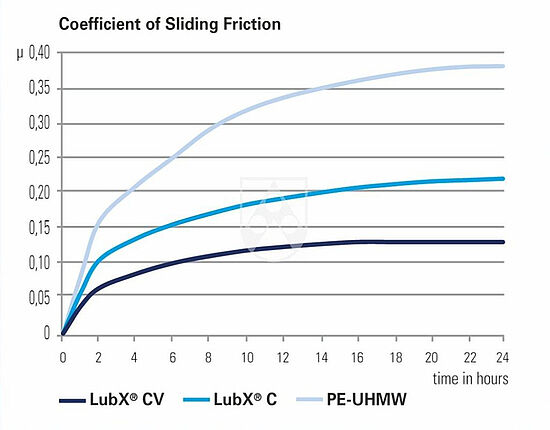

Extremely low coefficient of sliding friction

Above all, LubX® CV stands out due to the extremely low coefficient of sliding friction of μ: 0.13. The material was tested at a speed of 0.5 m/s and surface pressure of 0.5 MPa, significantly higher values than those of the usual testing procedure, to adapt the test to the high requirements. The application-oriented test shows that, in comparison with the other materials tested, LubX® CV has by far the lowest coefficient of sliding friction and the shortest run-in phase. Under these testing conditions, a standard PE-UHMW achieves a coefficient of sliding friction of μ: 0.37.

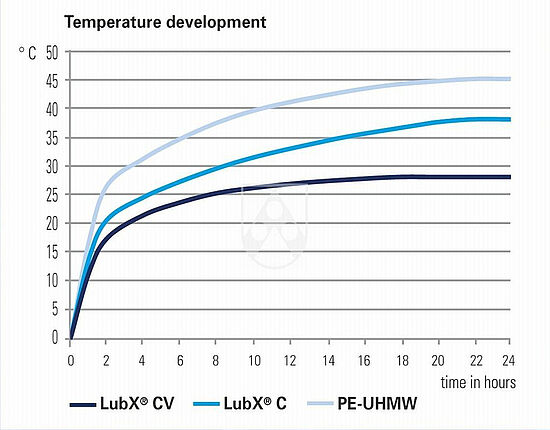

Low temperature development and high wear resistance

During the sliding friction coefficient test, an infrared sensor measured the temperature development directly on the friction surface of the sample without contacting it. The temperature of LubX® CV did not rise above 28° C during the test and was up to 17° C lower than the temperature of the other material samples. In addition, the LubX® CV testing block showed hardly any wear, even after 24 hours. The material's low temperature development and high wear resistance are beneficial for the service life of the system and increase the maintenance intervals.

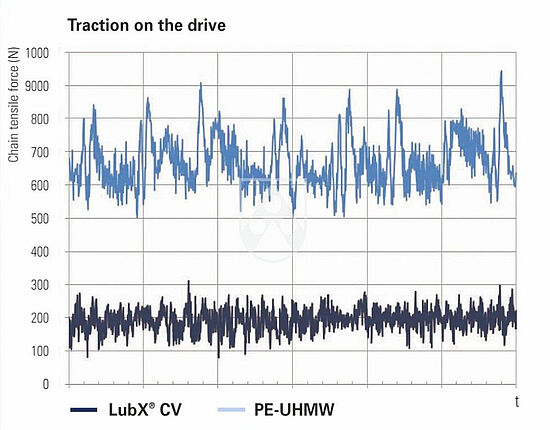

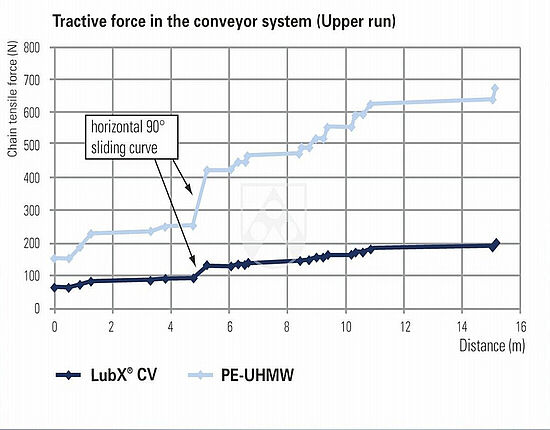

Efficient use of energy and high process stability

In times of rising energy costs, the efficient use of energy is a crucial factor. To measure the tensile force on the drive, LubX® CV was compared with a standard PE-UHMW on an application-oriented conveyor belt system. The mean value measured for LubX® CV was under 30 percent of the value measured for PE-UHMW. The energy consumption of the drive was also proportionately lower for LubX® CV.

In addition, the significantly decreased amplitudes of the measured curve for LubX® CV are proof of significantly improved process stability, decreased strain on the conveyor system and decreased noise development. Stick-slip movements are avoided.

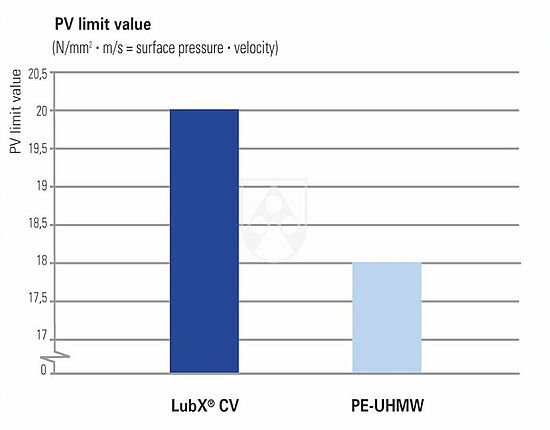

Higher velocities and pressure loads

The results prove that LubX® CV maintains its excellent sliding characteristics even under increased loads and can significantly improve the performance and productivity of systems. With its special characteristics, this new material makes it possible for conveyor systems, plants and machinery used in handling technology and automation to be operated at higher velocities and pressure loads. As the material is food hygiene compliant according to 10/2011/EU, 1935/2004/EC and the FDA, it can be used for applications with direct contact to food in the food processing industry without any problems.

New benchmark for sliding materials

With LubX® CV Röchling sets new standards for sliding materials and proves its application-oriented know-how of plastics. The plastic processor's new development expands the range of sliding materials for conveyor systems. As early as 2012 Röchling presented the sliding materials LubX® S und LubX® C, the sliding characteristics of which were specifically optimised for their respective friction partner.