Anyone who has ever been in a storm by the sea knows how loudly the wind can whistle round your ears. Wind is power. And this power can be put to use in wind-turbine systems. However, the systems must also withstand this power when generating energy. Reliable and powerful technology is needed. Which is why leading manufacturers use pultruded profiles by Röchling in their rotor blades. They are then fit for the next stiff breeze.

Actually, one cannot see from rotor blades what load they are under. From a distance all that can be seen normally is even rotation. But appearances are deceptive: wind speeds of up to 90 km/h, blade-tip speeds of up to 300 km/h, strong UV radiation and weather conditions make heavy demands on rotor blades. Engineers and technicians must therefore plan and design so that the rotor blades are efficient, reliable and safe in operation, even when under heavy loads. An important component for this comes from Röchling in Haren.

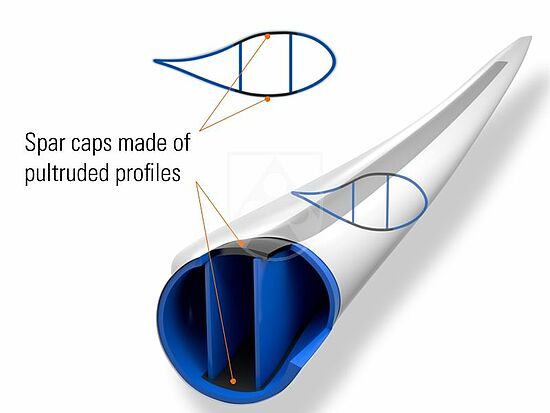

Leading manufacturers of wind-turbine systems use for so-called rotor blade spar caps pultruded profiles of carbon-reinforced (CFRP) or glass-reinforced (GFRP) Durostone® by Röchling. Rotor blade spar caps are used as stabilising elements on the inside of the rotor blades and can withstand extreme tensile forces. They thus reduce flexing of the rotor blades under high wind pressure and contribute to the systems’ operating safety and performance.

To make best use of the properties of the glass or carbon fibres, Röchling processes these to make pultruded profiles, which may be several hundred metres long. These are rolled up for transport and later cut by the customer to the right length for the respective rotor blade. Such a profile is only between 50 and 200 mm wide. A number of these profiles are laid side by side or one on top of the other to a form a so-called spar cap and then bonded to the inside of the rotor blade to form a unit. It is then fit for the next stiff breeze.

Contact

We would be happy to inform you in detail about the properties and possible uses of our Durostone® pultrudes profiles.

➜Inquiry: Durostone® pultruded profiles

More information on pultruded profiles for spar caps