Foamlite® vehicle construction sheets

Made of the lightweight plastic Foamlite® – for light and efficient commercial vehicles

Lightweight construction plays a key role in the development of modern commercial vehicles. The lower the weight, the lower the fuel consumption and environmental pollution for the same higher load capacity. We support the development of light and powerful commercial vehicles with our vehicle construction sheets made of Foamlite®.

Foamlite® is a closed-pore foamed plastic that combines low weight with high mechanical stability. Vehicle construction sheets made of Foamlite®:

- Reduce the weight of your commercial vehicle

- Optimise the load capacity

- Are robust and durable

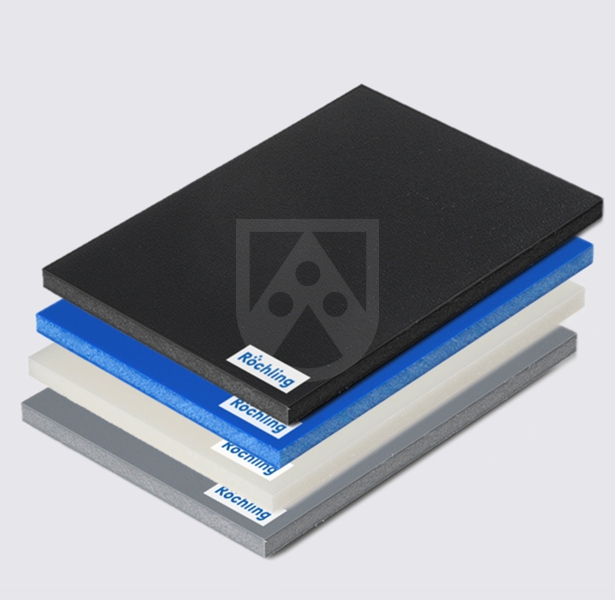

Foamlite® vehicle construction sheets are available in many different formats, thicknesses, colours:

- Sheet thicknesses: 6 – 30 mm

- Widths: up to 2000 mm

- Lengths: According to customer needs, theoretically unlimited, no waste

- Surface: Surface grained on both sides with high scratch resistance or slip-resistant "cubic grain" surface

Application areas – Foamlite® vehicle construction sheets

Commercial vehicles:

Our vehicle construction sheets made of Foamlite® are used in commercial vehicles such as:

- Transport vehicles, service vans, workshop vans, delivery vans

- Caravans, motor homes, camper vans

- Lorry trailers

- Horse trailers / horse transporters

Structures and components:

Depending on the vehicle, Foamlite® vehicle construction sheets are used for structures and components including:

- Wall cladding

- Door cladding

- Interior cladding

- Flooring

- Partitions

- Shelving systems

- Doors with V-groove

Properties – Foamlite® vehicle construction sheets

Application examples – Foamlite® vehicle construction sheets:

Very high abrasion resistance

Surfaces in commercial vehicles must withstand high mechanical wear and tear in many areas over the long term. Tests in our in-house materials laboratory show that Foamlite® vehicle construction sheets have significantly higher abrasion resistance in comparison with tested conventional plywood (textured coated board) vehicle construction sheets.

Built-in hinge

Foamlite® has a "built-in" hinge. All that is required is a 90 degree milled V-notch. This means it is very easy to make doors with V-grooves, for example. This saves time in the manufacturing process and eliminates additional material costs for hinges, screws and rivets.

Technical data – Foamlite®

Properties | Testing method | Unit | Foamlite® |

Density | DIN EN ISO 1183-1 | g/cm³ | 0.65 |

Moisture absorption | DIN EN ISO 62 | % | <0.1 |

E-module | DIN EN ISO 527 | MPa | 1100 |

Shore hardness | DIN EN ISO 868 | Scale D | 70 |